Product

Polyethylene

Introduction

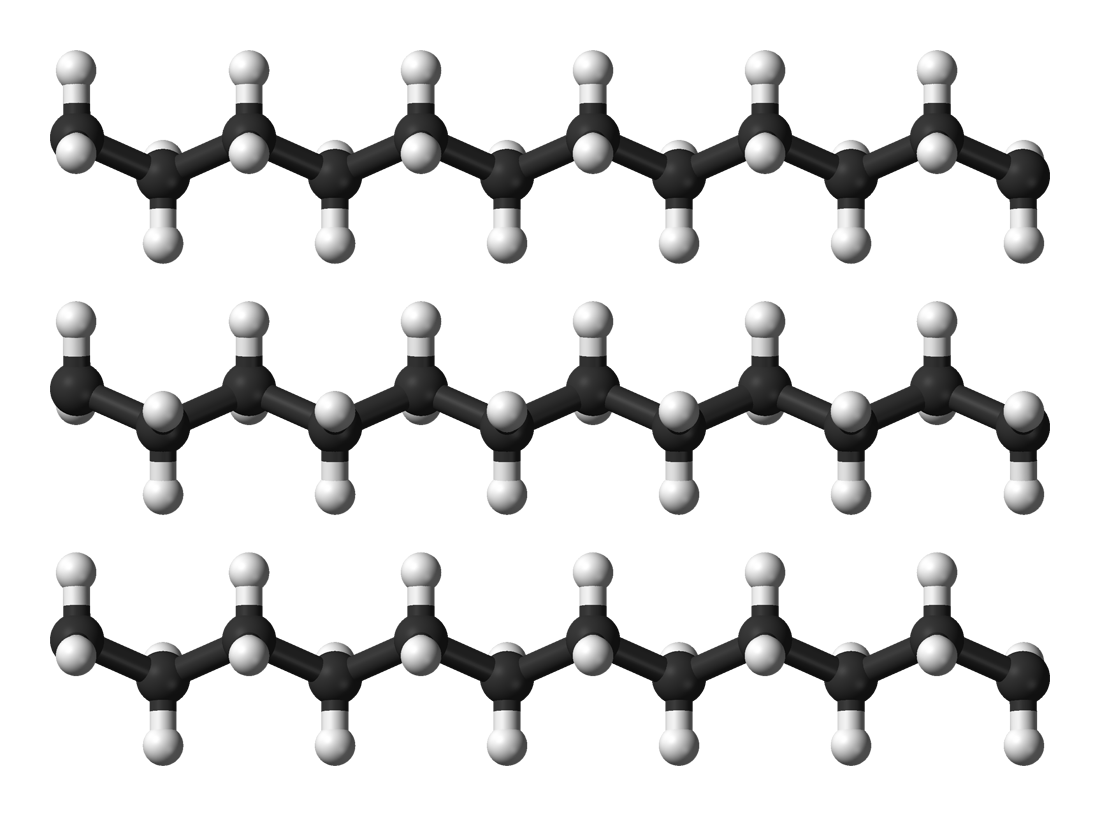

Polyethylene is a widely-used synthetic polymer with a simple chemical structure, consisting of long chains of ethylene monomers. It is a versatile material known for its excellent chemical resistance, low cost, and ease of processing, making it a cornerstone of the plastics industry.

-

Preparation using traditional method

The traditional method of producing polyethylene involves the polymerization of ethylene gas under high pressure and temperature in the presence of a catalyst, typically a transition metal compound. This process yields various forms of polyethylene, such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE), depending on the reaction conditions.

-

Reaction

During the traditional polymerization process, ethylene monomers are subjected to high pressure and temperature, causing them to form covalent bonds with each other, leading to the creation of long, branched, or linear polymer chains. Catalysts play a crucial role in controlling the chain structure and molecular weight of the resulting polyethylene.

-

Disadvantages of traditional method

One significant drawback of the traditional method is its energy-intensive nature, as it requires high-pressure reactors and consumes a substantial amount of fossil fuels. Additionally, the catalysts used in this process may contain toxic or environmentally harmful components, contributing to pollution and environmental concerns.

-

Preparation using Green method

The green method of polyethylene production offers a more environmentally friendly alternative by employing renewable resources and sustainable processes. One such approach involves using plant-derived ethanol as a feedstock, which can be converted into ethylene for polymerization.

-

Reaction

In the green method, ethylene can be obtained from plant-based ethanol through dehydration and subsequent oligomerization processes. This ethylene can then undergo polymerization to form polyethylene, mirroring the traditional process but with a reduced environmental footprint and reliance on non-renewable resources.

-

Advantages of Green method

The primary advantage of the green method is its sustainability and reduced environmental impact. By using renewable resources and minimizing the reliance on fossil fuels, this approach significantly lowers greenhouse gas emissions and reduces the environmental burden associated with polyethylene production.

-

Applications

Polyethylene is a versatile polymer used in various applications, including packaging materials, plastic bags, containers, pipes, and as an insulating material in electrical cables. Its widespread use in industries and everyday life highlights its importance in modern society, and the development of greener production methods is a promising step towards more sustainable plastic production.