PRODUCT

Polycarbonate

Introduction

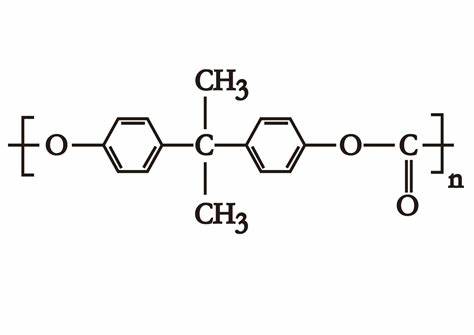

Polycarbonate is a versatile and durable thermoplastic polymer that is known for its transparency, high impact resistance, and heat resistance. It is commonly used in a wide range of applications, including eyeglass lenses, compact discs, and various industrial and consumer products. Polycarbonate is derived from the condensation polymerization of bisphenol A (BPA) and phosgene, resulting in a linear, high-molecular-weight polymer with excellent mechanical properties.

-

Preparation using traditional method

Polycarbonate is traditionally prepared through a two-step synthesis process. In the first step, bisphenol A (BPA) is combined with an excess of phosgene in a solvent such as methylene chloride. This results in the formation of polycarbonate oligomers. In the second step, these oligomers are then subjected to further polymerization under heat and vacuum conditions to produce high molecular weight polycarbonate.

-

Reaction

The reaction involves the condensation of bisphenol A and phosgene to form polycarbonate oligomers, followed by further polymerization to produce the final polycarbonate polymer. The process requires the use of toxic and hazardous chemicals like phosgene, making it less environmentally friendly and posing health and safety risks.

-

Disadvantages of traditional method

The traditional method of polycarbonate preparation involves the use of phosgene, a highly toxic and hazardous chemical. This poses environmental and health risks during production. Additionally, it generates byproducts that must be carefully managed, and the process may not be considered sustainable due to these environmental concerns.

-

Preparation using Green method

Green methods for polycarbonate production aim to reduce the environmental impact by using alternative and more sustainable processes. One such green method involves the use of non-phosgene routes, where alternative reactants and solvents are employed, minimizing the use of toxic chemicals and improving overall sustainability.

-

Reaction

Green methods for polycarbonate production can involve alternative reactants like diphenyl carbonate and different catalysts to replace phosgene. The reaction is more environmentally friendly, using fewer hazardous chemicals and promoting a safer working environment for production.

-

Advantages of Green method

The primary advantage of green methods for polycarbonate production is the reduction of environmental and health hazards associated with traditional methods. By minimizing the use of toxic chemicals and promoting a safer working environment, these green methods contribute to more sustainable and responsible manufacturing practices.

-

Applications

Polycarbonate, whether produced using traditional or green methods, finds extensive use in various industries. Its excellent properties, including optical clarity, impact resistance, and high-temperature performance, make it a preferred material for applications such as eyeglass lenses, automotive components, medical devices, and even in construction materials like skylights and safety glazing. The choice of production method can influence the material's overall sustainability and environmental impact, making green methods increasingly attractive for applications where eco-friendliness is a priority.