Product

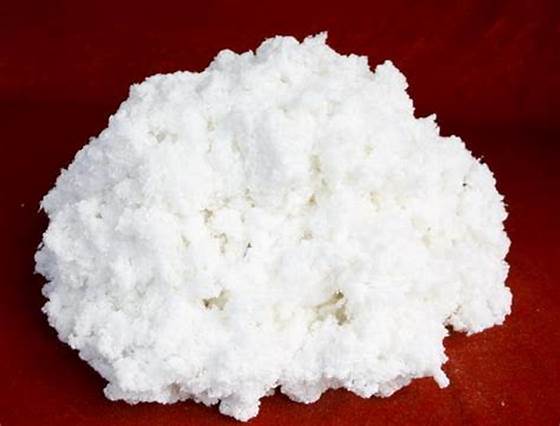

Paper Pulp

Introduction

Paper pulp is a versatile material used in the production of various paper and cellulose-based products. It is primarily composed of cellulose fibers, hemicellulose, and lignin, all derived from plant sources, predominantly wood. These components are separated and processed to create the pulp, which serves as the foundation for the paper-making industry.

-

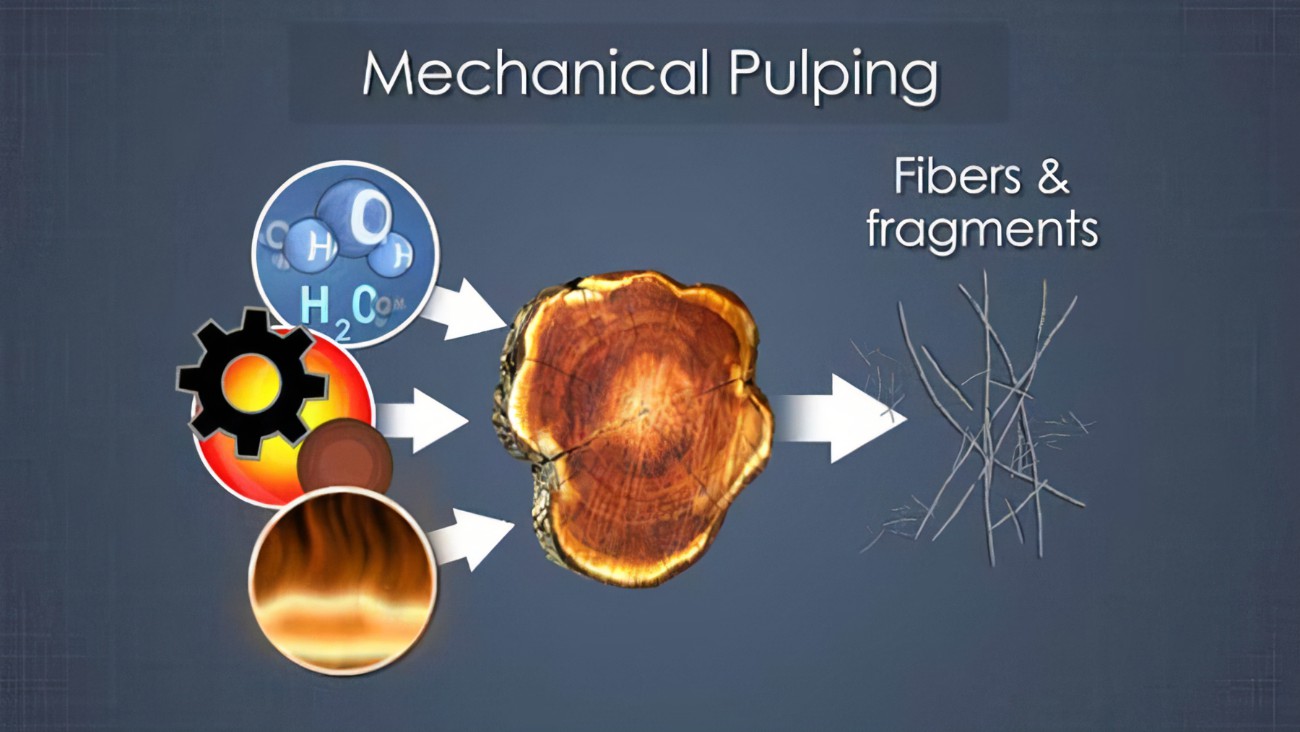

Preparation using traditional method

Traditionally, paper pulp is prepared through a labor-intensive process that involves mechanical and chemical methods. Wood logs or chips are first mechanically broken down into smaller pieces. These wood fragments are then subjected to chemical treatments with strong alkali, such as sodium hydroxide and sodium sulfide, in a process known as the Kraft process. This chemical pulping method is effective but has several environmental drawbacks.

-

Reaction

The reaction in the traditional paper pulp preparation involves the breakage of wood fibers and the dissolution of lignin in a mixture of strong alkali and high-temperature conditions. This process separates cellulose from other wood components, resulting in a pulp that can be used for paper production. However, it generates large amounts of pollutants and waste, contributing to environmental concerns.

-

Disadvantages of traditional method

The traditional method of paper pulp preparation has several disadvantages, including the generation of toxic chemical waste, high energy consumption, and the release of harmful emissions into the environment. The chemicals used can be hazardous, and the disposal of waste products poses environmental challenges. Additionally, deforestation and the depletion of natural resources for wood sourcing are concerns associated with this method.

-

Preparation using Green method

To address the environmental concerns associated with traditional methods, green or eco-friendly methods for paper pulp preparation have gained popularity. One such approach involves using enzymes, such as cellulases, to break down the lignin and facilitate the separation of cellulose from wood fibers. This method reduces the use of harmful chemicals and energy-intensive processes.

-

Reaction

The reaction in the green paper pulp preparation method involves the application of enzymes, primarily cellulases, which selectively degrade the lignin and hemicellulose components of wood. This enzymatic process is milder and more environmentally friendly, resulting in a pulp with less chemical residue.

-

Advantages of Green method

The green method of paper pulp preparation offers several advantages, including reduced environmental impact, lower energy consumption, and the potential for using alternative and sustainable sources of biomass. Enzymatic methods are more selective, produce fewer pollutants, and minimize the need for harsh chemicals, making it a more sustainable and eco-friendly approach.

-

Applications

Paper pulp, whether prepared through traditional or green methods, serves as the foundation for a wide range of products, including various types of paper, cardboard, packaging materials, and even textiles. The versatility of paper pulp allows it to be utilized in industries like publishing, packaging, and textiles, contributing to the production of everyday items such as newspapers, books, cardboard boxes, and clothing. The shift towards green pulp preparation methods aligns with the growing global focus on sustainability and reducing the environmental impact of manufacturing processes.