Product

Ethylene glycol

Introduction

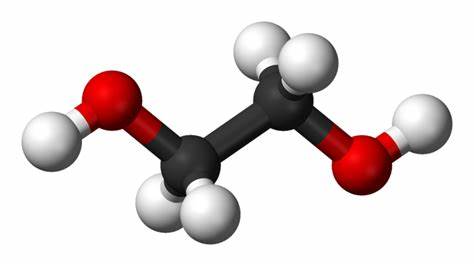

Ethylene glycol, also known as ethane-1,2-diol, is a simple organic compound with the chemical formula C2H6O2. It is a colorless, odorless, and sweet-tasting liquid that is commonly used as an antifreeze in automotive cooling systems and as a precursor in the production of polyester fibers and resins. Ethylene glycol is a diol, meaning it has two hydroxyl (OH) groups, and it is a critical industrial chemical due to its versatility in various applications.

-

Preparation using traditional method

Ethylene glycol is traditionally prepared through the hydration of ethylene oxide, a reaction that involves high-temperature and pressure conditions. Ethylene oxide reacts with water in the presence of a strong acid or base catalyst to form ethylene glycol. This process is energy-intensive and generates substantial waste, making it environmentally unfriendly.

-

Reaction

The traditional method of preparing ethylene glycol involves the addition of water to ethylene oxide, a chemical reaction that typically occurs at temperatures around 150°C and high pressures. The reaction is catalyzed by either a strong acid, such as sulfuric acid, or a strong base, like sodium hydroxide. The outcome of this reaction is a mixture of ethylene glycol, diethylene glycol, and various byproducts.

-

Disadvantages of traditional method

One of the main disadvantages of the traditional method for preparing ethylene glycol is its energy-intensive nature and the generation of significant waste byproducts. Additionally, the use of strong acids or bases as catalysts can pose environmental and safety concerns. These factors make the conventional production process less sustainable and more harmful to the environment.

-

Preparation using Green method

A more environmentally friendly and sustainable method for producing ethylene glycol involves the hydration of ethylene oxide using a green catalyst, such as zeolites or various metal-organic frameworks (MOFs). These catalysts enable the reaction to proceed at lower temperatures and pressures, reducing energy consumption and minimizing waste generation.

-

Reaction

When using green catalysts like zeolites or MOFs, the hydration of ethylene oxide to produce ethylene glycol occurs at milder conditions compared to the traditional method. Lower temperatures and pressures are employed, which significantly reduce energy consumption and waste production. This greener approach provides a more sustainable way to obtain ethylene glycol.

-

Advantages of Green method

The use of green catalysts in the production of ethylene glycol offers several advantages. It is a more sustainable and environmentally friendly method that reduces energy consumption, minimizes waste, and avoids the use of hazardous strong acids or bases as catalysts. This approach aligns with the principles of green chemistry and contributes to a cleaner and more efficient production process.

-

Applications

Ethylene glycol has a wide range of applications, with its primary use being as an antifreeze in automotive cooling systems. It prevents freezing and overheating of engines by lowering the freezing point and raising the boiling point of water. Additionally, ethylene glycol is utilized in the manufacture of polyester fibers, resins, and various industrial processes where its properties as a versatile solvent and chemical intermediate are valuable. It also finds applications in the pharmaceutical and cosmetics industries.