Product

Acetic acid

Introduction

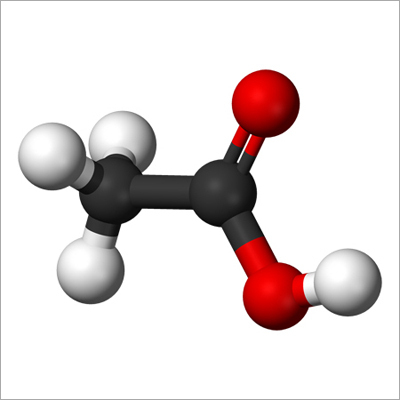

Acetic acid, also known as ethanoic acid, is a colorless organic compound with a pungent smell and a sour taste. It is a fundamental component of vinegar, and its chemical formula is CH3COOH. Acetic acid is a weak acid and an important chemical in various industrial, culinary, and laboratory applications.

-

Preparation using traditional method

Traditionally, acetic acid has been prepared through the fermentation of ethanol by acetic acid bacteria. This process involves the oxidation of ethanol to acetic acid, often carried out in wooden barrels containing vinegar. The reaction is catalyzed by the enzyme alcohol dehydrogenase. The traditional method has been widely used for producing vinegar and is still relevant in artisanal production.

-

Reaction

The chemical reaction involved in the traditional preparation of acetic acid is C2H5OH + O2 → CH3COOH + H2O. In this reaction, ethanol (C2H5OH) is oxidized in the presence of oxygen (O2) to produce acetic acid (CH3COOH) and water (H2O).

-

Disadvantages of traditional method

The traditional method of acetic acid production, while effective, can be slow and less controlled than modern industrial processes. It relies on the natural activity of acetic acid bacteria, making it susceptible to contamination and variations in product quality. It also requires significant time and resources to produce large quantities of acetic acid.

-

Preparation using Green method

A greener and more controlled method for acetic acid production involves the carbonylation of methanol in the presence of a catalyst, such as rhodium or iridium. This method is commonly used in industrial settings and offers better efficiency and control over the reaction.

-

Reaction

The green method for acetic acid production involves the reaction CH3OH + CO → CH3COOH, where methanol (CH3OH) and carbon monoxide (CO) react in the presence of a suitable catalyst to yield acetic acid (CH3COOH).

-

Advantages of Green method

The green method is advantageous because it allows for precise control over the reaction, resulting in higher yields of acetic acid with consistent quality. It is more suitable for large-scale industrial production, reduces waste and byproducts, and minimizes the environmental impact compared to traditional fermentation methods.

-

Applications

Acetic acid has a wide range of applications, including its use as a preservative, food flavoring agent, and in the production of synthetic fibers, plastics, and solvents. It is also used in the manufacture of various chemicals, such as acetic anhydride and acetate esters. In the pharmaceutical and cosmetic industries, it is employed in the production of medicines, perfumes, and skincare products. Additionally, acetic acid plays a critical role in the production of vinegar for culinary purposes and is used in cleaning and disinfection products.